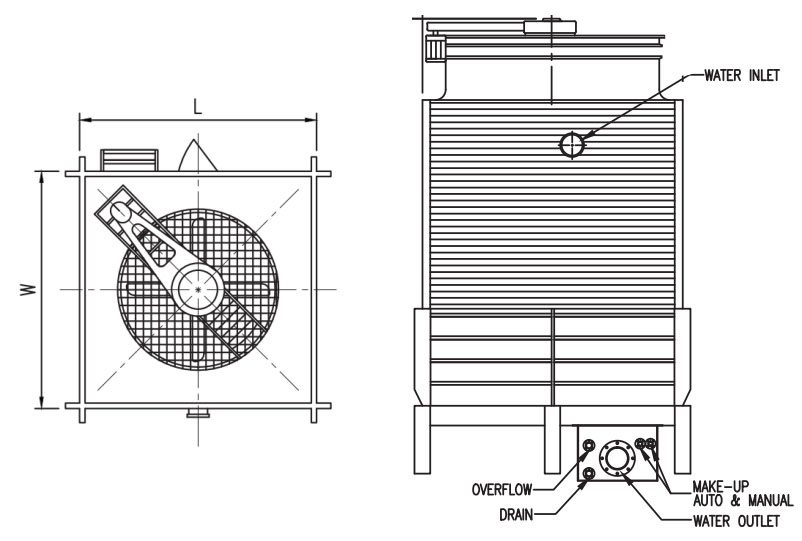

Counterflow Cooling Tower

Quantity

Features

Tower Construction

Tower casing body is made out of F.R.P. (Fiberglass Reinforced Plastics) which is corrosion free, very durable and yet light. The body is coated with a special epoxy consist of anti-ultraviolet agent and more resistant to UV sunlight. Th e tower main structure frame is using steel which has undergo hot dipped galvanization (HDG) process to prevent rust.

Cold Water Basin

The cold water basin is constructed from F.R.P. (Fiberglass Reinforced Plastics) which is corrosion free and is supported by HDG steel frame underneath. Th e cold water basin is also slopping basin to ensure the dirt and sediments trapped inside the basin is being diverted towards the depressed sump in the centre of basin. Th e depressed sump will prevent air lock from occurring during the tower operation. Th e sump is also supplied with suction strainer, makeup water ball valve, overflow and drain connection. Th ere is a high quality special mat above the cold water basin that will absorb most of the water drop noise.

Mechanical drive system

Fans are of axial type designed to deliver air performance at low noise level. Fan blades material shall be FRP as standard and aluminium alloy as optional. . All fan blades are factory balanced before shipped out. Th e fan is

operating inside a fan stack enclosure to streamline the air entry while maintaining maximum fan efficiency.

V belt drive system

Which connects the cast iron pulleys at the motor and fan is contained inside FRP belt cover. Th is is to ensure that the belts are protected from moist discharge air. Optional aluminium alloy pulleys are available.

Motor

Is of TEFC weather proof squirrel cage for 3 phase 415 V / 50 Hz power supply. Th e motor shall be located outside the discharge air stream below the belt cover to prolong the motor life and ease of maintenance and access.

Fan bearing

Has a lubrication delivery system from external point outside the fan stack to the fan bearing to allow grease top up to be carried even when the fan is in operation.

Fills

The film type cellular fill is made of air vacuum forming Ultra Violet (UV) Light resistant PVC sheets which have corrugated surface. Th e surface has been specially designed to spread the water droplet from hot water basin evenly.

The fills are bonded into modular blocks and install in the tower as per design. Th e specially designed PVC drift eliminator can reduce the water loss due to carry over within 0.001% with very little air pressure drop.

Water distribution system

All nozzles are designed to be with special orifice to avoid getting clogged easily. Moreover the nozzles are located inside the tower therefore it is not expose to dirt and environmental pollution.

Dimension

Counterflow CT: 1 Cell Cooling Tower

Counterflow CT: 2 Cell Cooling Tower

Counterflow CT: 3 Cell Cooling Tower

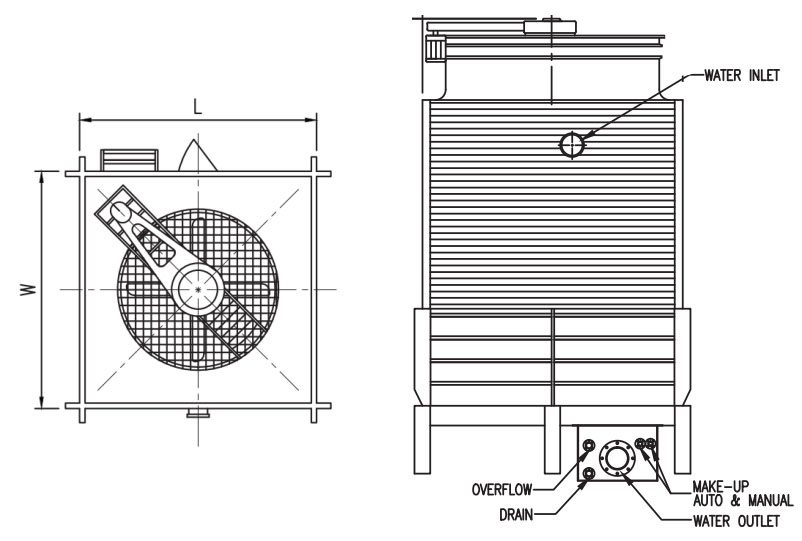

Tower Construction

Tower casing body is made out of F.R.P. (Fiberglass Reinforced Plastics) which is corrosion free, very durable and yet light. The body is coated with a special epoxy consist of anti-ultraviolet agent and more resistant to UV sunlight. Th e tower main structure frame is using steel which has undergo hot dipped galvanization (HDG) process to prevent rust.

Cold Water Basin

The cold water basin is constructed from F.R.P. (Fiberglass Reinforced Plastics) which is corrosion free and is supported by HDG steel frame underneath. Th e cold water basin is also slopping basin to ensure the dirt and sediments trapped inside the basin is being diverted towards the depressed sump in the centre of basin. Th e depressed sump will prevent air lock from occurring during the tower operation. Th e sump is also supplied with suction strainer, makeup water ball valve, overflow and drain connection. Th ere is a high quality special mat above the cold water basin that will absorb most of the water drop noise.

Mechanical drive system

Fans are of axial type designed to deliver air performance at low noise level. Fan blades material shall be FRP as standard and aluminium alloy as optional. . All fan blades are factory balanced before shipped out. Th e fan is

operating inside a fan stack enclosure to streamline the air entry while maintaining maximum fan efficiency.

V belt drive system

Which connects the cast iron pulleys at the motor and fan is contained inside FRP belt cover. Th is is to ensure that the belts are protected from moist discharge air. Optional aluminium alloy pulleys are available.

Motor

Is of TEFC weather proof squirrel cage for 3 phase 415 V / 50 Hz power supply. Th e motor shall be located outside the discharge air stream below the belt cover to prolong the motor life and ease of maintenance and access.

Fan bearing

Has a lubrication delivery system from external point outside the fan stack to the fan bearing to allow grease top up to be carried even when the fan is in operation.

Fills

The film type cellular fill is made of air vacuum forming Ultra Violet (UV) Light resistant PVC sheets which have corrugated surface. Th e surface has been specially designed to spread the water droplet from hot water basin evenly.

The fills are bonded into modular blocks and install in the tower as per design. Th e specially designed PVC drift eliminator can reduce the water loss due to carry over within 0.001% with very little air pressure drop.

Water distribution system

All nozzles are designed to be with special orifice to avoid getting clogged easily. Moreover the nozzles are located inside the tower therefore it is not expose to dirt and environmental pollution.

Dimension

Counterflow CT: 1 Cell Cooling Tower

Counterflow CT: 2 Cell Cooling Tower

Counterflow CT: 3 Cell Cooling Tower

Counterflow CT: 4 Cell Cooling Tower