Air-Cooled Screw Chiller

Quantity

Features

Product Ranges

Air cooled screw chillers provides wide range of cooling capacity, from 338kW up to 1038kW, can be integrated easily with various type of application. Each compressor provides 4-steps, 8-steps or continuous (25%~100%/12.5% ~100%) capacity control delivers the precise capacity to match the building cooling/heating load.

Screw Compressor

The screw compressor with simple and robust construction design have resulted in low noise, high reliability and durability operation. Other than this, the thermal motor temperature monitoring, discharge temperature protection, phase sequencer distinguish screw compressor with its outstanding feature.

Two Stage Liquid Injection

All FASC air cooled screw chiller is equipped with two stage liquid injection to maintain normal discharge temperature. Advanced liquid injection is achieved by a bypass line for delivering liquid refrigerant to suction line (1st stage) and compression chamber (2nd stage) to reduce high compression heat. This will prevent compressor’s failure from getting high temperature in the compressor.

PLC Control

PLC controller is installed on all standard FASC units to execute setting, operating status viewing and protect critical components in response to internal or external signals: high discharge temperature protection, compressor overload protection, high/low pressure protection, water flow error, anti-freeze protection, oil level switch, and automatic defrost functions.

Easy Maintenance

Wired LCD Touch-Screen controller equipped with various operating mode, operating status viewing, timer setting, self diagnosis and alarm history. This will greatly reduce the commissioning and troubleshooting time.

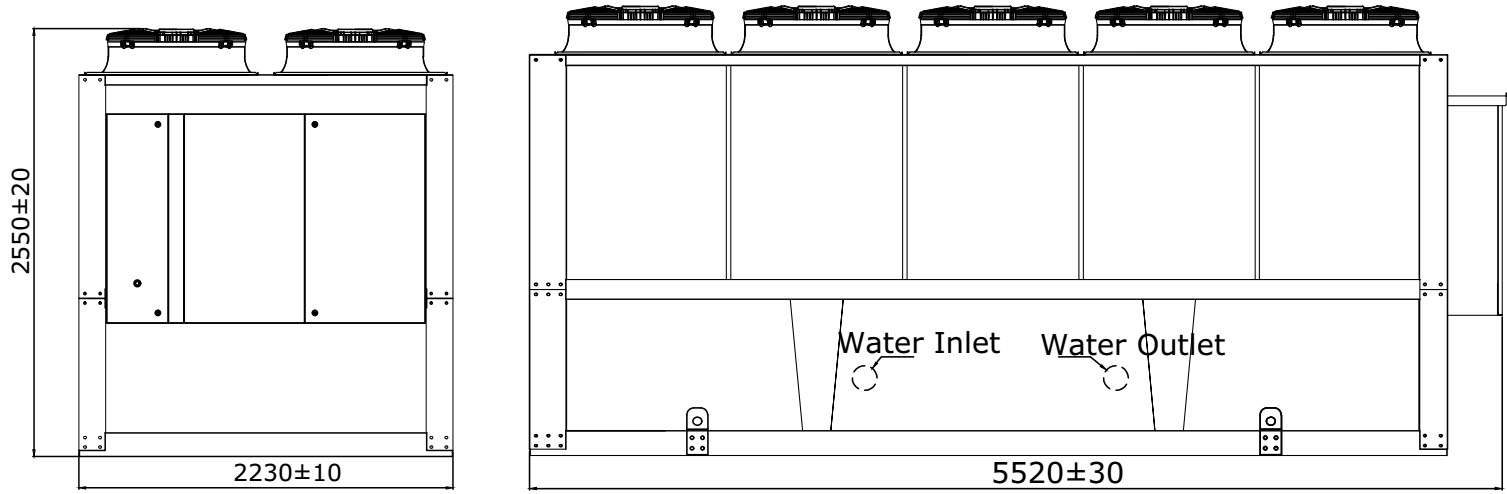

Dimension

.png)

.png)

Product Ranges

Air cooled screw chillers provides wide range of cooling capacity, from 338kW up to 1038kW, can be integrated easily with various type of application. Each compressor provides 4-steps, 8-steps or continuous (25%~100%/12.5% ~100%) capacity control delivers the precise capacity to match the building cooling/heating load.

Screw Compressor

The screw compressor with simple and robust construction design have resulted in low noise, high reliability and durability operation. Other than this, the thermal motor temperature monitoring, discharge temperature protection, phase sequencer distinguish screw compressor with its outstanding feature.

Two Stage Liquid Injection

All FASC air cooled screw chiller is equipped with two stage liquid injection to maintain normal discharge temperature. Advanced liquid injection is achieved by a bypass line for delivering liquid refrigerant to suction line (1st stage) and compression chamber (2nd stage) to reduce high compression heat. This will prevent compressor’s failure from getting high temperature in the compressor.

PLC Control

PLC controller is installed on all standard FASC units to execute setting, operating status viewing and protect critical components in response to internal or external signals: high discharge temperature protection, compressor overload protection, high/low pressure protection, water flow error, anti-freeze protection, oil level switch, and automatic defrost functions.

Easy Maintenance

Wired LCD Touch-Screen controller equipped with various operating mode, operating status viewing, timer setting, self diagnosis and alarm history. This will greatly reduce the commissioning and troubleshooting time.

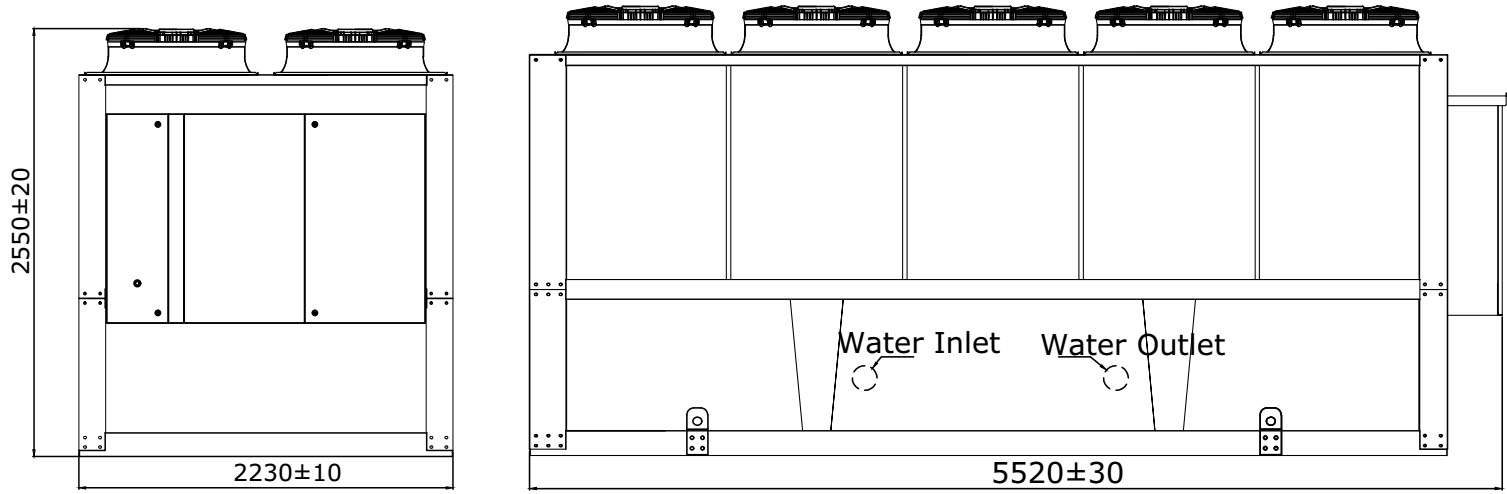

Dimension

.png)

.png)